Nov

The EV Supply Chain Crisis No One’s Talking About (But Should Be)

-

Anshuman / 2 months

- November 27, 2025

- 0

- 5 min read

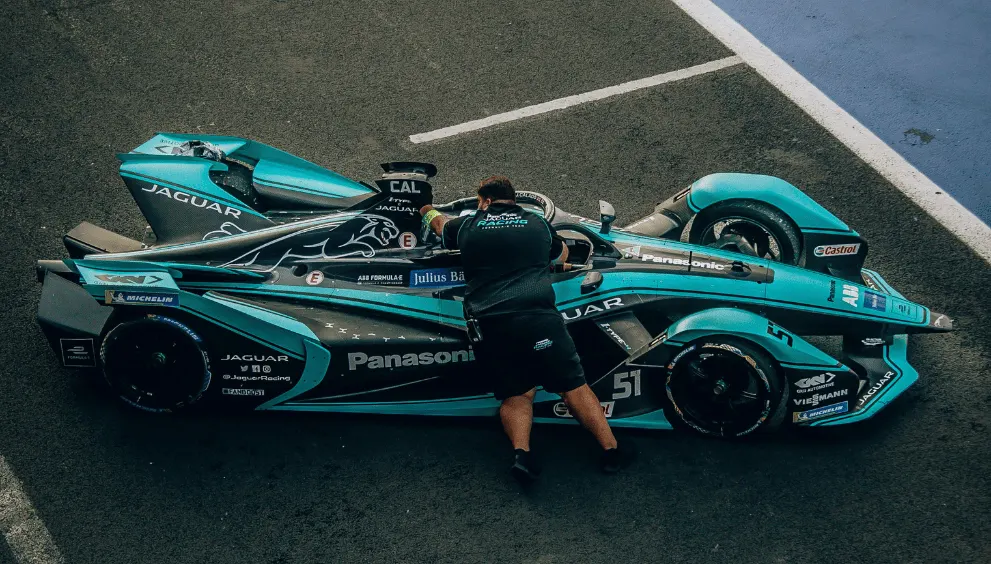

I mean isn’t it a well known fact that electric vehicles (EVs) are the wave of the future, am I right? Zero emissions, attractive designs, tech-heavy interiors – What’s not to love? Here’s the catch that nobody seems to want to talk about: While the demand for EVs is rising, the supply chain for

EVs are at a crisis point to keep up with demand.

That’s right, we said it. There is a drama behind the scenes in the world of EV cars and it‘s a big one.

EVs Are Blowing Up – But Is the Industry Ready?

Now let’s look at the numbers. In 2020, worldwide EV sales were about 2 million. Now fast forward to 2040? That number is expected to skyrocket to 73 million (thanks are in order to Goldman Sachs for the data). And by 2030, almost 66% of newly sold vehicles will be EVs or hybrids. Insane, right?

But with fast growth comes great responsibility – and some serious headaches in logistics.

Why EV Supply Chains Are a Whole New Beast

If you’re asking, “Why don’t car companies just build a lot more EVs?” The answer is much more complex than you think.

Manufacturers of gas-powered vehicles have decades developed supply chains that have no issues sourcing metals, plastics, and rubber, but EVs are different- EVs are much more complex – fundamentally more semis, more lithium-ion batteries, and other high-tech components and assemblies. On the one hand semis are sensitive, brittle, and need a very particular handling process while in transit. On the other hand, for delivery, a lithium-ion battery is considered exploratory hazardous materials, which cannot just be placed on Jordan truckRad 557 and shipped to cross-country distribution centers.

So, effectively automotive manufacturers are playing an entirely different game of logistics, and most are still way behind on how to play the game. So, that means we proudly invited you into our community of experts in electrified business.

Most of the Good Stuff Comes from Asia

Another twist in this story: Much of the components for electric vehicles, particularly chips and batteries, are made in Asia. Think China, South Korea, Japan. This means shipping plans have to change, and quickly.

Businesses will require new supply routes, new packaging solutions, different handling, and even more workers who know how to move these components from A to B safely.

Furthermore, many of these materials must be obtained from somewhere, and, with so much demand, there is a global shortage of these materials. And, if you toss in some geopolitical strain (like the never ending U.S.-China trade tussles), the ease of producing EVs doesn’t seem to be a reality.

The Luxury EV Angle: What the Rich Are Worried About

Next, let‘s examine the luxury EV market – the Teslas, Lucid Motors, Rivians, etc., not just vehicles but tech-thrones. These vehicles come equipped with luxury amenities and finishes, advanced software, and unbelievable acceleration. Nevertheless, the very high-end EVs must have very high-end materials, such as rare earth metals, and China asserts the rare element minerals.

That is why luxury car manufacturers start to panic when the situation starts to heat up and the trade restrictions start to gum up everything. What does this mean to them? Fewer rare earths = fewer luxury EVs = unhappy ALMOST royalty customers.

All in all: not even the ultra-luxury side of the EV market is immune to the chaos.

Everyone’s Talking Sustainability – But Can Supply Chains Keep Up?

Another buzzword that is Gen Z approved? Sustainability! Everyone wants to go green – and that is great. But it is difficult to build sustainable supply chains.

To work towards decreasing emissions and keeping up to demand, EV‘s are now trying to:

- Source materials ethically (no dubious mining contracts please)

- Reduce emissions in shipping and production

- Re-purpose components especially batteries

- Make factories closer to where people are actually buying EV’s

Spoiler alert – this is going to take time, money and serious partnership with governments, car makers and logistics professionals.

The New Kids in town: India, Thailand and beyond.

With the EVs race on, the automakers are exploring new grounds. The emerging markets like India, Thailand and Indonesia are proving to be the new EV manufacturing hubs.

Why? They are emerging markets, they are better incentivized and they have not been exploited yet.

But, with that opportunity comes new challenges – different regulations, unknown infrastructure and hastily assembling supply chains. Whoever can get there fastest and adapt will shift the advantage. The rest? Well they just maybe stuck in a shipping holding pattern.

So, what’s the solution?

- Diversify suppliers. Don’t have all of your chips (yes, literally) in one basket.

- Partner smarter. Collaborate with a logistics partner who knows EVs.

- Think bold. Digital twins, real-time tracking, automation… they all need

- to be part of the process going forward.

- Localize. This can be done through factories or by developing storage, but localization is critical.

- Train the people. Because dealing with EV pieces is fundamentally different from dealing with aspects relating to traditional car stuff.

In each case, relying upon historied ways won’t work: reconstructing the supply chain will involve a 360 degree reinvention of the wheel.

Final Thoughts: The EV Revolution Needs a Reality Check

I’ve got to be honest – we love EVs. What’s not to love? The sleek designs, the environmental impact, the ridiculous torque. That’s all. But if we don’t want to talk about the messy logistics problems, we will have a really uncomfortable ride ahead.

The future of mobility is electric, hands down. But wherever you see a shiny luxury EV, behind that is a complex, messy, and unpredictable supply chain still trying to catch up.

If we want that ‘future’ to be sustainable and scalable, we need to pay attention to what is happening behind the scenes – shipments, semiconductors, rare minerals, and yes, the paperwork.

Until we figure all that out, the EV dream isn’t really ready to take the ride.